LED and laser burn-in test system built for small capacity expandable to high capacity.

System delivered with

- Reliable precise multichannel current source

- Easy to use software application

- Python API

- 3m drive cable

- 600W total output power

- Ethernet cable for remote control

- Calibration Certificate

- Documentation

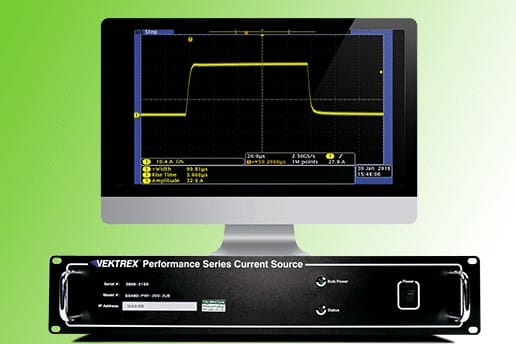

Reliable Precise Current Source

- 8 individually controllable source channels

- 4A maximum current per source channel

- high voltage per source channel

- 600W total output power

- DC/CW and pulse/QCW operation

- Built in patented device protection

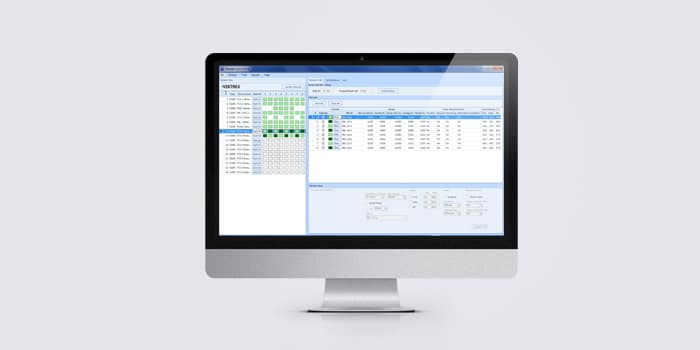

Easy to Use Software Application

- Configure operational parameters for individual source channels

- Create and save recipes for use

- Start / stop individual source channels

- User defined locations identify test device location (eg chamber at my desk)

- Data file per source channel output in .CSV format

- Accurate duration timers to automatically stop test at completion or pause/restart

- Unattended 7/24 operation with restarts in case of failure

- Programmable ramp / no reverse bias

Applicable Devices

- LED

- COB chip on board

- VCSEL

- Laser / Sensor

- Devices in series (high voltage)

- Quantum Cascade Laser

Industry, Standards and Applications

- Research and Development – semiconductor device, light emitting diode, vertical cavity surface emitting laser, UV-leds

- Automotive

- Military

- Pre-LM-80 test

- LM-80 reliability test compliant

Additional Information

Designed specifically to control and test current driven semiconductor devices, the Burn-In Test System is configurable with any SpikeSafe DC, Continuous Pulse or Performance series multichannel current source. These multichannel current sources offer multiple individually controllable source channels. With a wide range of currents and voltages available, system configurations and usage is simplified. SpikeSafe-ness patented transient protection rapidly shuts down power to devices, within ns, when an anomaly is detected. These digitally controlled sources provide a flexible, scalable foundation that meet stringent burn-in test protocols.

Burn-In Test System Customization – contact Vektrex

- Vektrex offers a wide range of currents and voltages

- Sources also available in single channel models

- Scale up with additional source channels use software as the commander

- Failsafe Temperature Monitoring and Shutdown – Protect devices from thermal runaway conditions and over/under temperature n

- Device temperature monitoring – add data acquisition to include thermal data with reliability data

- Add auxiliary bulk power supply to increase total output power flexiblity to 1000W per source channel

- Increase MCV to 400V per source channel

- Individual source channel isolation

- Interlocks for operator safety

Burn-in Test System for LEDs / UV-LEDS

Vektrex Burn-in Test System is easily customized for LED burn-in to include any or all of the following capabilities.

- LM-80 test compliance

- Spikesafe protections rapidly shutdown when a device anomaly is detected

- Data protection in the event of power loss

- Thermal protections

- High voltage to drive devices in series

Burn-In Test System for Laser Diodes

Laser diodes such as bar, VCSEL and QCL (quantum cascade lasers) require special handling. Vektrex Burn-in Test System is easily customized for laser burn-in to include any or all of the following capabilities.

- Optical Monitoring with a photodiode

- Interlocks for operator safety

- Isolation

- Device temperature monitoring with failsafe shutdown

- Common cathode