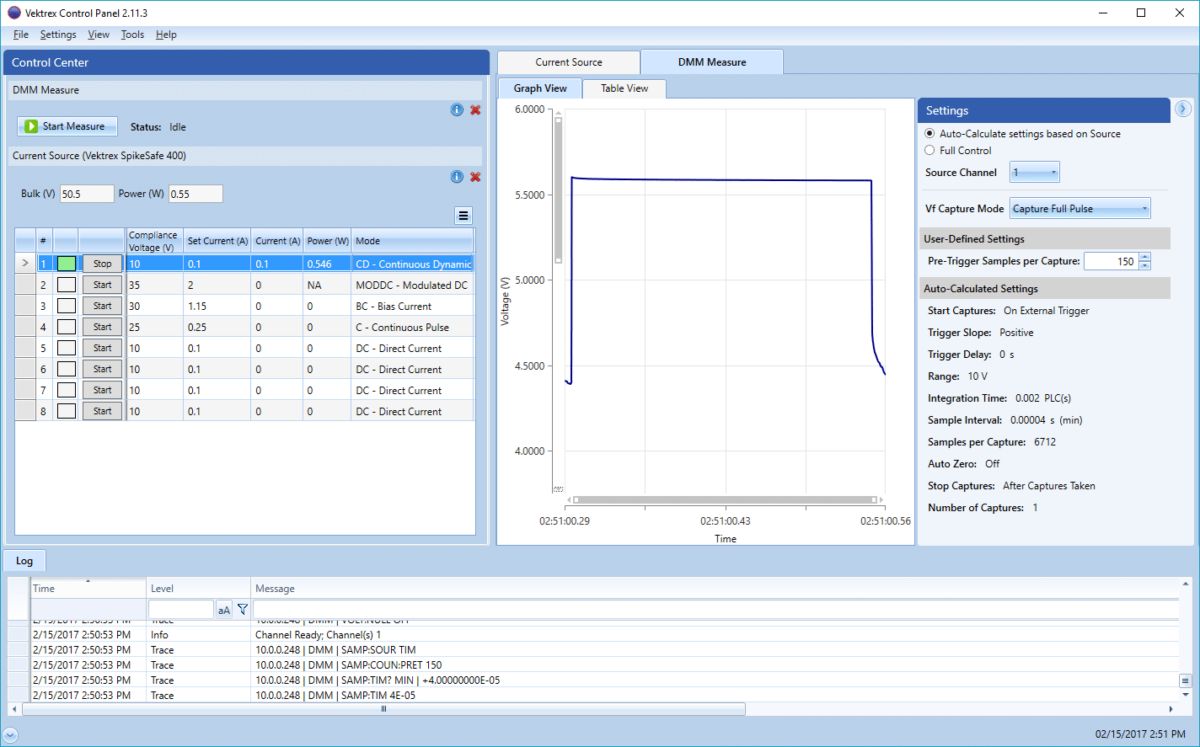

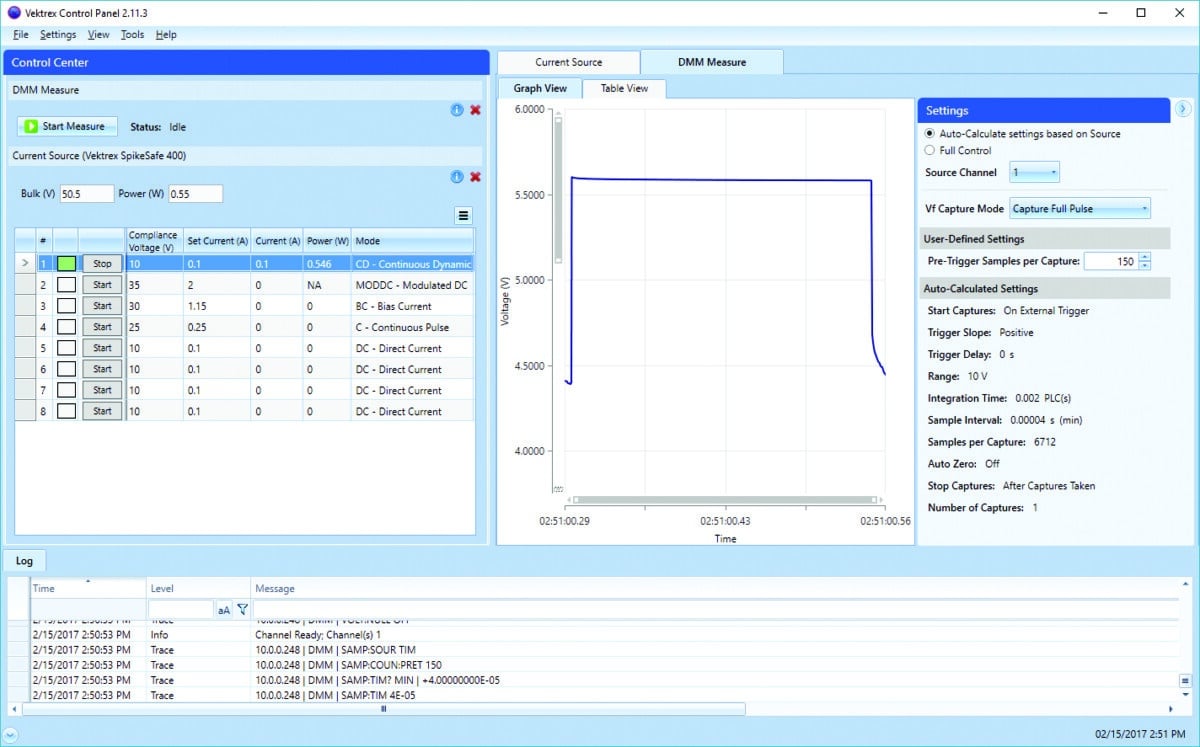

Included with every Vektrex source, source measure unit and pulser, the Vektrex-developed Control Panel software application provides an intuitive, graphical interface out of the box. Designed for seamless instrument control and real-time data visualization, no coding is required. Monitor device under test voltage and current during ramp-up, steady-state, and ramp-down phases in both constant current and pulsed modes.

With just a few clicks, users can:

- Generate I-V, L-I, and custom plots on the fly

- Apply built-in statistical tools to create publication-ready graphs in seconds

- Export data effortlessly to CSV or image formats for lab notebook documentation

- Save and recall “Recipes” to simplify complex test sequences and ensure repeatability

Whether you’re characterizing devices or fine-tuning pulsed measurements, Control Panel streamlines your workflow—reducing setup time and enabling faster, more consistent results.

Connect, Configure, Control and Monitor with Control Panel

Vektrex Control Panel Software is a powerful, user-friendly application designed to connect, configure, control, and monitor the electrical characteristics of your test device. It provides full access to all supported operating modes of your pulsed source or source measure unit, serving as a central hub for streamlined, reliable instrument control and efficient test execution..

To get started, simply enter the IP address

associated with your source(s) and set your desired voltage and current.

If you are using an SMU, configure the true differential digitizer.

From there, choose between any of the 50+ operating modes supported by your device and begin to see just what your devices are capable of. Learn More About SpikeSafe Operating Modes

Control Panel allows users to control their SpikeSafe, providing ultimate capability over your current source. Control Panel has various features that simplify virtually any load testing process. The application can set source current and compliance voltage. With the simple interface and remarkably easy-to-use settings, Control Panel can apply settings to a single or multiple-source channel module. Control Panel focuses on providing users proper testing consistency and ease of use with features that allow you to save presets, letting you save and recall all current source settings.

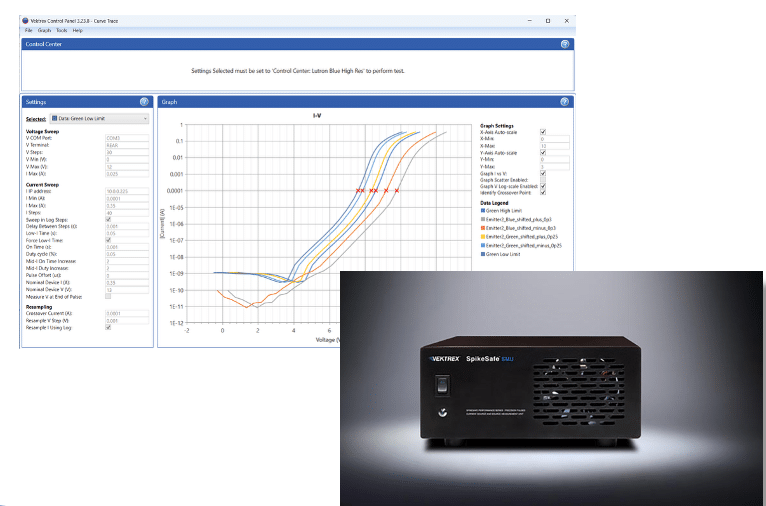

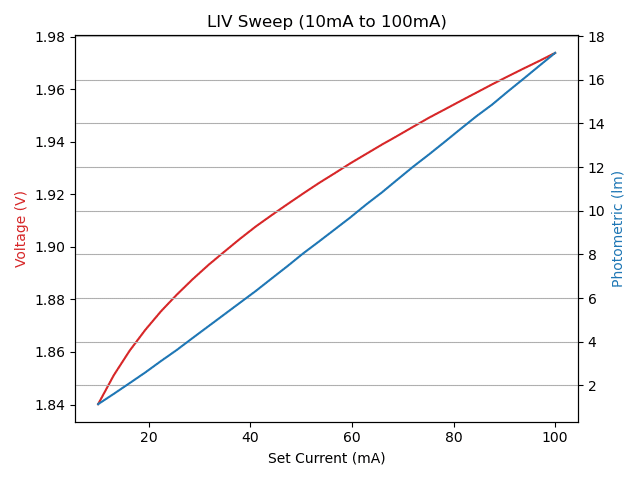

Curve Trace Tool Application

Curve trace tool now available as an add-on application to Control Panel. Vektrex curve trace tool combines low-current constant-voltage measurements transitioning to pulsed current measurements at higher currents. The novel hybrid curve trace approach provides optimized diagnostic coverage across device failure modes. It offers increased accuracy and allows testing at higher currents safely.

More information about the curve trace tool.

Semiconductor Device Electrical Characterization With Control Panel

Using Vektrex software, it is easy to perform device electrical characterization.

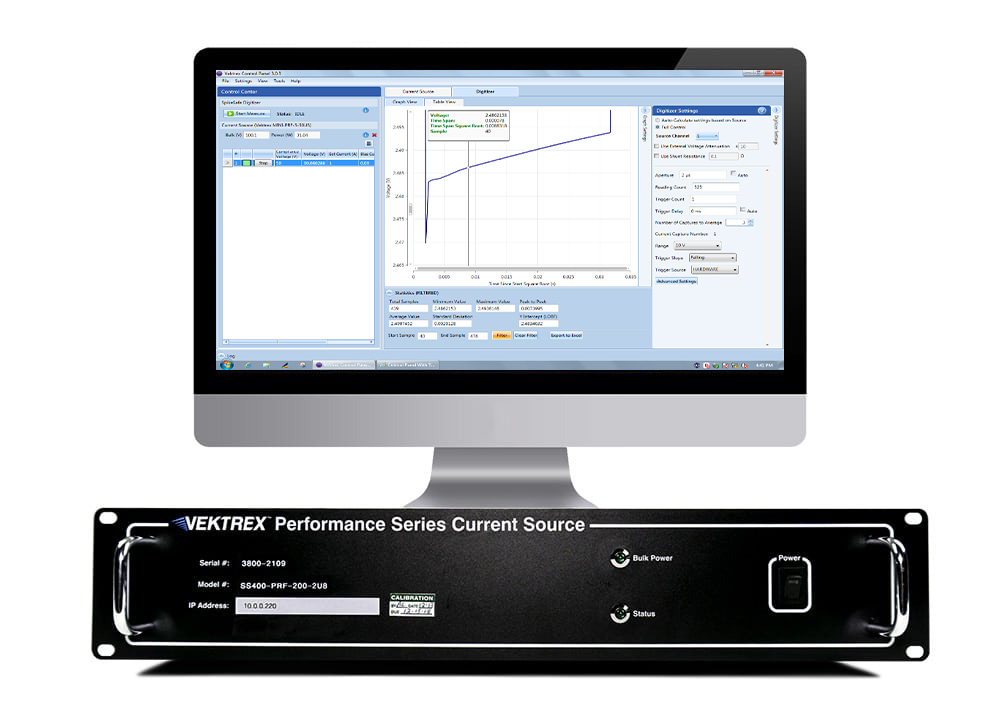

Measure Forward Voltage With Control Panel Software

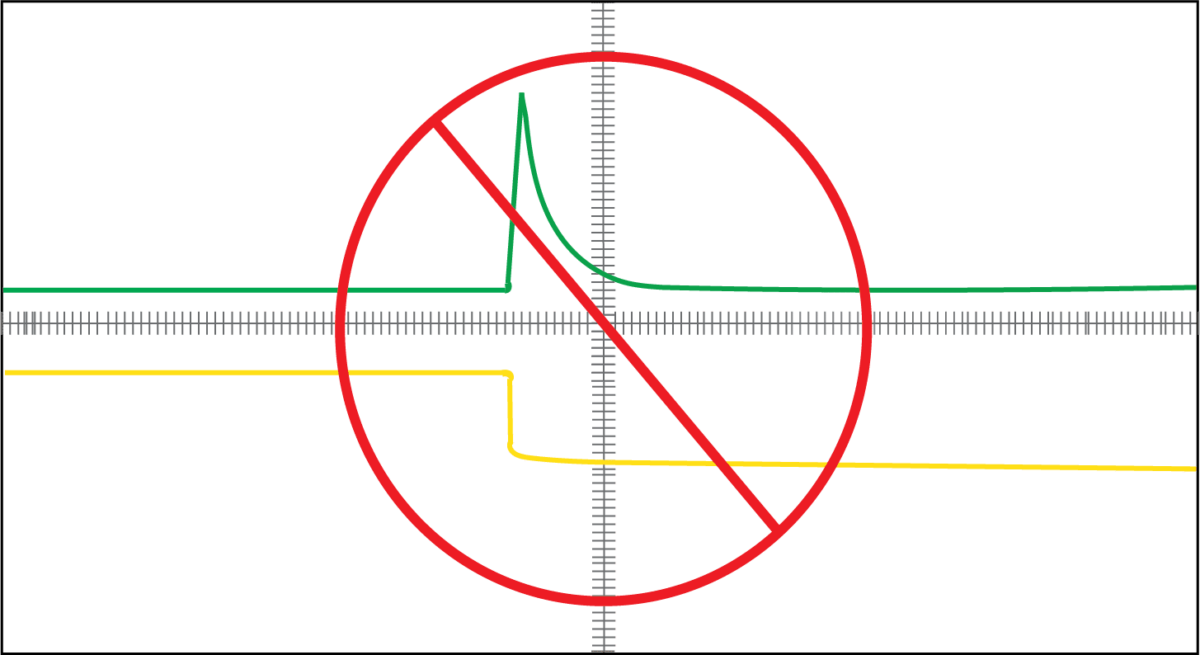

Measuring and viewing forward voltage (Vf) is important for many applications. With the enhanced Control Panel software application, view device forward voltage and heating over the pulse. Visualizing the pulse shape achieves an important goal – ensuring an ideal pulse shape for your application. Pulse shape is key to measurement repeatability. Visualizing the pulse shape will confirm the load tuning to avoid overshoot and compensate for cable impedance.

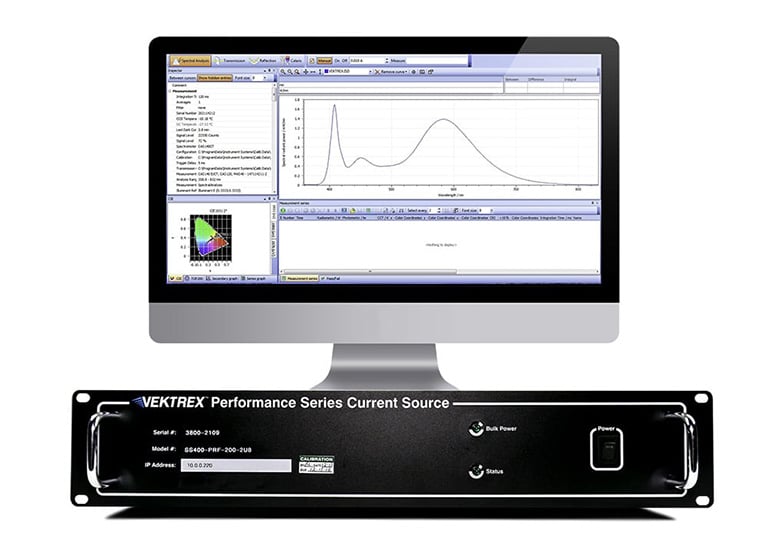

Vektrex’s easy-to-use Control Panel software application provides turn-key control of SpikeSafe current sources, SMU, and optional high speed spectrometers. This software pairing provides familiar LED and laser diode source/measure capabilities – with the added benefit of high-speed sampling, pulse visualization, and light measurement.

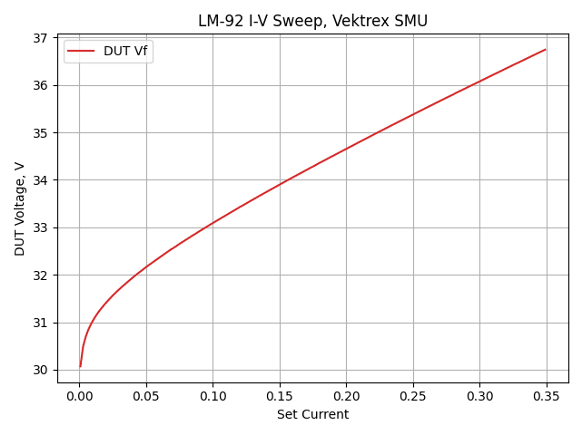

Generate IV Curves With Control Panel

Modern day source measure units that supply short precise current pulses enable true constant-temperature I-V plots to be generated quickly and easily.

The Control Panel Software Application makes it possible to generate an IV Curve with your SpikeSafe Source Measure Unit without any additional equipment, programming or sequence code.

Easily validate vendor IV Curves to ensure your product development and research efforts are efficient.

Visit our blog to learn more about using a fast precise pulsed SMU to improve high-power IV characterization and for a step-by-step video guide of how to generate an IV curve in Control Panel using the SpikeSafe SMU.

Photodiode-based Light Measurement with Control Panel

Use Vektrex Source Measure Unit with two digitizers combined with the Control Panel software application to capture light from a photodiode and generate LIV curves.

Spectrometer-based Light Measurement with Control Panel

Vektrex Control Panel software application integrates spectrometer based light measurements in the following ways:

When using Instrument Systems CAS Spectrometer, Vektrex source measure unit may be controlled by Instrument Systems SpecWin Pro software application.

Additional flexibility and operating modes are available by using SpecWinPro Manual Mode. In this case, Vektrex source measure units are driven by Vektrex Control Panel software application.

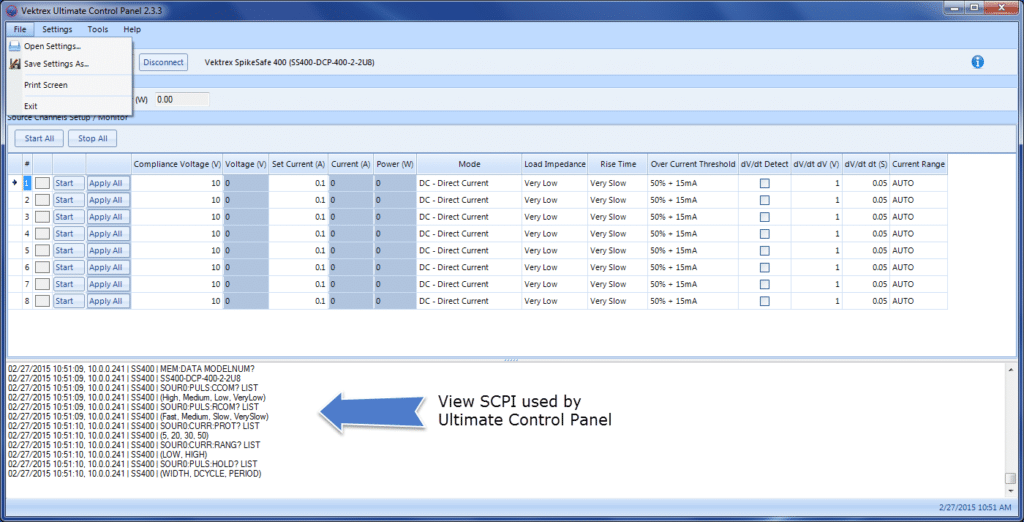

Quickly Develop Custom Testing Applications

Custom software development is simplified by viewing and cutting/pasting the SCPI commands and sequences. Control Panel also includes the “Enable SCPI Logging” button for retrieving your settings and saving them to the desktop. The Control Panel software application will help simplify training and the process of getting to know the specifics of your SpikeSafe.

Custom software development is simplified by viewing and cutting/pasting the SCPI commands and sequences. Control Panel also includes the “Enable SCPI Logging” button for retrieving your settings and saving them to the desktop. The Control Panel software application will help simplify training and the process of getting to know the specifics of your SpikeSafe.

Control Panel and Junction Temperature

With Control Panel and Vektrex SMU with optional hardware integrated BIAS or measurement source, it is possible to measure junction temperature and view data never before seen. Check out the Junction Temperature Measurement Toolkit.

Transient Protection

Vektrex designed Performance Series Current Sources offer Spike Safe Transient Response. This Transient Response limits device damage when failures occur. Typical Constant voltage sources run in constant current mode. For example, a 1000% Current Spike, which can happen with typical constant voltage sources, will kill your devices. Other current sources with low capacitance are similarly prone to killing your devices from even a 400% current spike.

Spike Safe Current Sources provide features such as providing options to configure over current threshold and rapid voltage change detection. Spike Safe digitally-controlled current sources with fast protection drastically limit damage from current spikes and protect your LED, VCSEL and LIDAR devices during testing.

Load Tuning

To achieve good rise and fall times with minimal overshoot, Vektrex products include programmable compensation settings that can be set to accommodate a variety of load conditions. The ‘Load Impedance’ setting, accessed through the Control Panel Software Application, adjusts for cable length and load impedance.

The ‘Rise Time’ setting, also accessed through the Control Panel Software Application, controls the speed of the pulse rise and fall and shapes the rising edge. Slower settings provide slower, more controlled edges. These features make testing simple and safe.