Measurement repeatability is extremely important to achieve in order to save time and money while testing LEDs and laser diodes. SpikeSafe Current Sources and Source Measure Units make repeatable measurements easy to achieve.

3 Steps to Improved LED Measurements: Accuracy

Accuracy is a crucial part of the three steps to improved LED light measurements. Jeff Hulett, Vektrex CTO, narrates this three part webinar series on how to improve LED light measurements. Instrumentation and the selected measurement method are key factors to improving your measurements.

3 Steps to Improved LED Light Measurements: Power

Jeff Hulett, Vektrex CTO, teaches how to identify current source power limitations that may negatively impact your LED light measurements. Instrumentation and the selected measurement method are key factors to improving your LED light measurements. Sustained power is the foundation for improved LED light measurement.

3 Steps to Improved LED Light Measurements: Repeatability

Repeatability is key in improving LED light measurements. Jeff Hulett, Vektrex CTO, narrates this three part webinar series on how to improve LED light measurements. Instrumentation and the selected measurement method are crucial factors to improving your measurements.

Why You Should Stop Averaging Your Measurements

Learn why you should stop averaging your forward voltage measurements and how SpikeSafe current sources can help you improve forward voltage measurement accuracy in this helpful webinar.

One and Done

One and done measurements indicate the need to get the most accurate possible Vf measurements as fast as possible. Commonly used current sources and source measure instruments produce varied measurements that require averaging to be useful.

The Industry Needs Better LED Measurements

Three hundred years ago global navigation was a dangerous undertaking. Ships sailing east and west had to determine their longitude by a tedious method known as dead reckoning. Errors were commonplace and calculations were typically off by a few percent at the end of a long voyage – often enough to make landing in port or on a rocky reef equally likely.

Is Your Light Measurement Method Undervaluing Your LEDs?

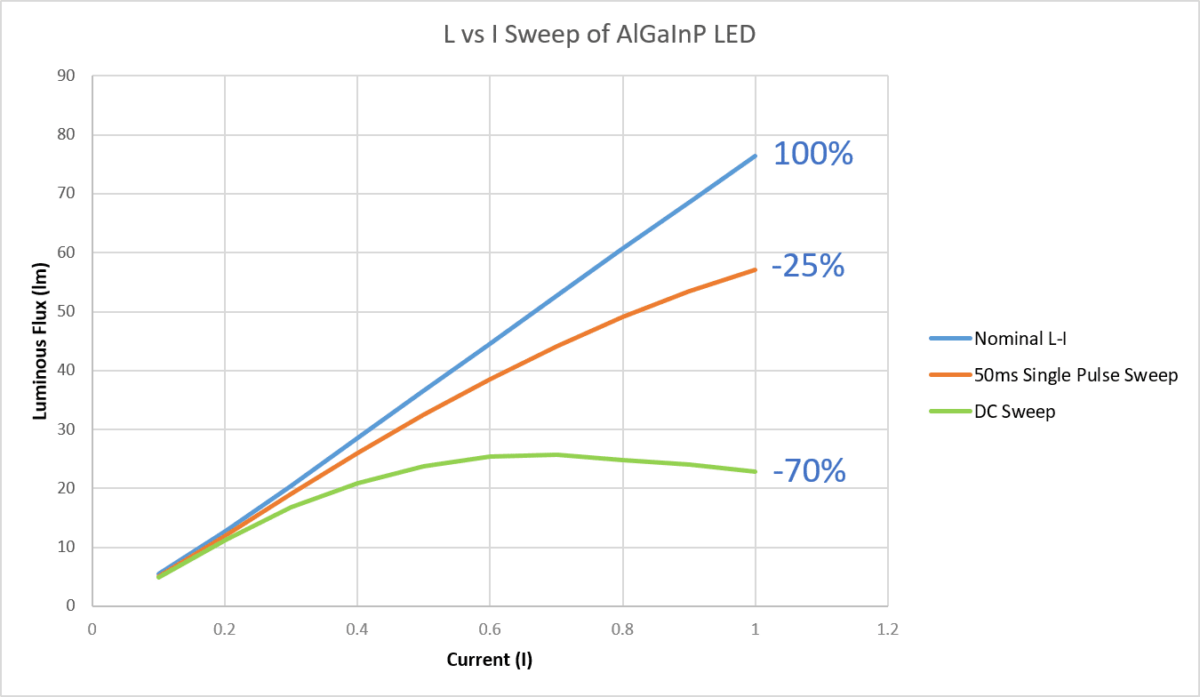

Measurements that were simple to perform with older LEDs are problematic or impossible to achieve with today’s high-efficacy LEDs because the LED junction and phosphors heat significantly during the measurement. Even when the heating is minimal, heated junctions and phosphors produce less light, and the light that is emitted is shifted in peak wavelength. This fundamental measurement challenge complicates the R&D task, by making it problematic to exchange measurement data, and by making it difficult to accurately rate LEDs at their true output.

Improved Photometric Testing for High-Power LEDs

Photometric testing standards first appeared in the late 1800’s; they were needed by the emerging gas lighting industry. Later standards focused on electric illumination. The traditional standardized photometric testing methods in use today, Commission International De’Leclairage (CIE) 127 and Illuminating Engineering Society of North America (IESNA) LM-79, were originally adapted from tests for incandescent lamps and other electric lamps. In these testing methods, the lamp is powered continuously and long stabilization times are mandated.

LM-85 Light Measurements for High Power LEDs

LM-85 is an Illuminating Engineering Society (IES) approved method for the Electrical and Photometric Measurements of High Power LEDs. The Commission Internationale de L’Eclairage (CIE) has a similar method named TC2-063. LM-85 focuses on the special needs related to getting light measurements for high power LEDs that require heat sinks for their normal operation. White LEDs and single color LEDs are included.

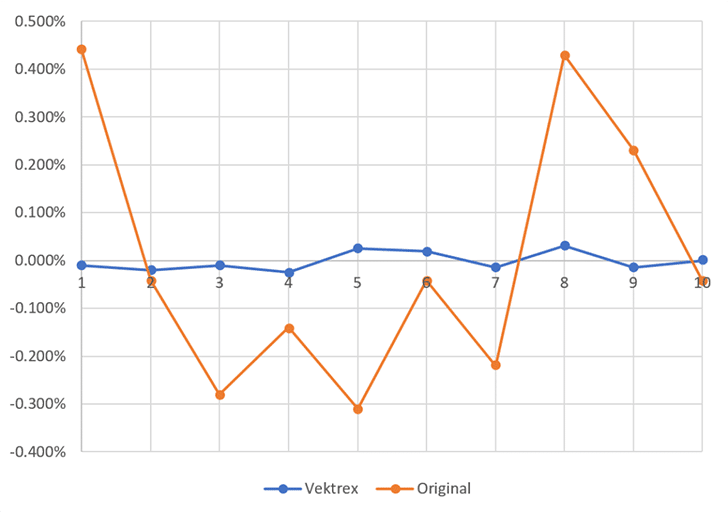

Standard Methods Describe How to Achieve Measurement Repeatability